Production Quality

This equipment automatically corrects and optimizes image quality such as focus and optical axis through real-time image analysis of the alignment error of the image sensor and lens of the camera module. It is operated in a clean room environment and implements fast production speed and stable optical quality through an automated system.

Since 2018, We have introduced automatic assembly robots to realize zero defect. Currently it consists of 2pcs of monitor automatic assembly robots and a camera automatic assembly robots.

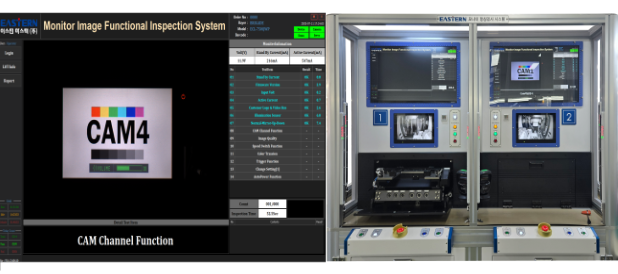

This is a system that automatically inspects and stores the monitor's image quality and main functions, such as resolution, color, brightness, current consumption, trigger, and audio. We apply a test evaluation list that matches the customer's requirements and produce products with consistent quality and performance, thereby increasing quality reliability.

Digital test equipment for determining pass and fail of focusing tolerance by camera focusing operator in production of camera. It is under applying in production line currently for camera focusing inspection.

Possible to produce equal quality products and equal performance products running camera performance evaluation lists.

Also, possible to produce each customer`s camera specification.

Waterproof test for producing products that meet quality standards considering the user environment.

All products are checked by automatic monitoring equipment.

To ensure quality of camera module, we conduct a through inspection using optical axis inspection equipment and make final modifications before shipping the product.

To verify reliability, continuous operation tests are conducted for 8 hours to 24.

All products are inspected with monitoring equipment.